LAG Fusion has got its start. The company is rooted in the production experience of Alluminio Zanardi S.r.l. that with over 40 years of activity in the market of aluminium intermediate cast products has been part of the wider business reality of L.A.G. S.p.A. since 2018. Both companies, part of a single representative, have now the opportunity to expand their own production potentials with the focus to offer a wide range of products and processing to their customers.

The history of LAG Fusion began in 1973 when the then Alluminio Zanardi S.r.l. established its own production site in the municipality of Buscate (MI), still today the heart of the activity. Since 1983 following a first revamp, production was converted in the aluminium melting cycle for the production of rolling slabs, obtained by the vertical semi-continuous casting process. The surface area of the processing plants currently covers more than 6.000 square meters.

Thanks to constant investment in technological upgrading, the company has achieved the current production structure with an annual capacity of 30.000 tons diversified in a wide range of aluminium alloys; the company mission has always been to pursue the most modern European and global quality standards with regard to quality, safety and environment.

Technological Cycle

LAG Fusion manufactures slabs in aluminium and aluminium alloys of different compositions, weighing up to 7 tons by MELTING. Metal originating both from primary activity and recycling of aluminium scrap collected from products at the end of their useful life is being used in the production process. Great care is drawn to the capacity of the installations to deal also with the material from recycling sources for the maximum respect of environment.

Quality control

The entire production process and the final testing are subject to a constant QUALITY CONTROL through the aid of an internal laboratory, equipped with state-of-the-art specific instruments for analyses and testing the manufactured metal.

Products

Production respecting our environment

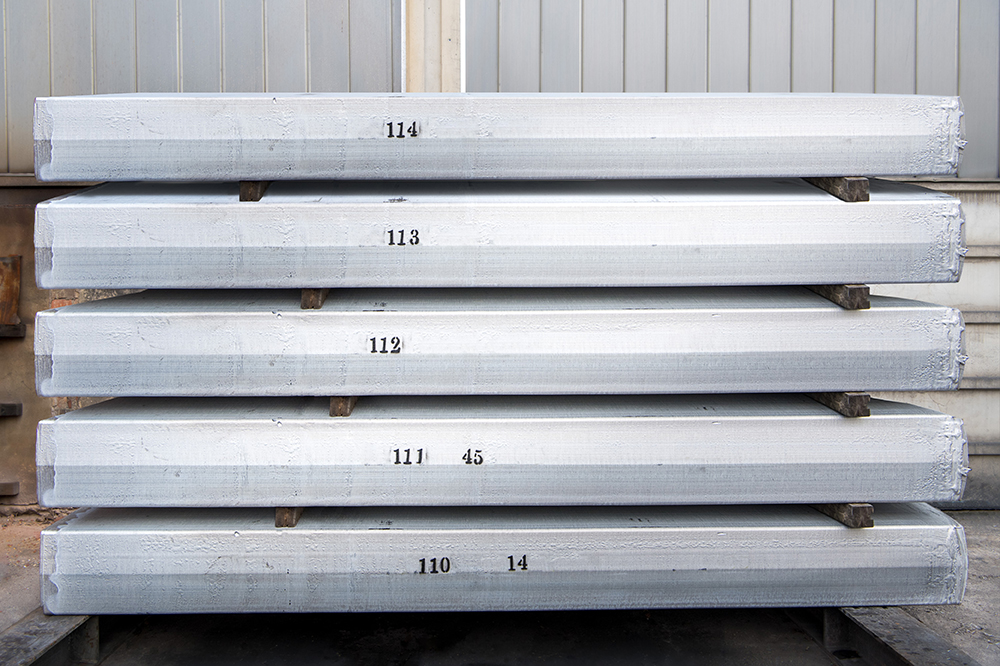

Slabs

Series 1000 – 3000 – 4000 – 5000

| WIDTH mm. | LENGTH mm. | THICKNESS mm. |

| 1050 mm. | From 4000 mm. to 5000 mm. | 370 mm. |

| 1100 mm. | From 4000 mm. to 5000 mm. | 390 mm. |

| 1150 mm. | From 4000 mm. to 5000 mm. | 370 mm. |

| 1230 mm. | From 4000 mm. to 5000 mm. | 370 mm. |

| 1320 mm. | From 4000 mm. to 5000 mm. | 370 mm. |

| 1350 mm. | From 4000 mm. to 5000 mm. | 390 mm. |

| 1450 mm. | From 4000 mm. to 5000 mm. | 370 mm. |

| 1530 mm. | From 4000 mm. to 5000 mm. | 370 mm. |

| 1560 mm. | From 4000 mm. to 5000 mm. | 420 mm. |

| 1630 mm. | From 4000 mm. to 5000 mm. | 370 mm. |